Hassle-Free Jacketless Rectangular Autoclaves for South America, Europe, the Middle East, Africa, and Asia

By: Priorclave North America

Category: Uncategorized

Many facilities prefer a rectangular chambered autoclave. For this reason, they end up with a steam-jacketed autoclave—even though they don’t really need a steam jacket. Non-jacketed rectangular autoclaves can give labs and facilities outside North America the form-factor they need without demanding the expense and waste of house steam or an independent generator. For most labs, in-chamber heating will prove much more energy efficient, more robust, and lower maintenance.

Priorclave offers non-jacketed autoclaves of all sizes with rectangular pressure vessels and in-chamber heaters. These autoclaves offer everything a more complex autoclave has to offer (fully programmable controls, one-touch media cycles, vacuum options, etc.) without the added expense and complications of an unneeded steam jacket system. No other company builds 350L and larger rectangular steam sterilizers with in-chamber heating.

Why you might want to go jacketless

While steam jackets have their place, that place might not be in your lab.

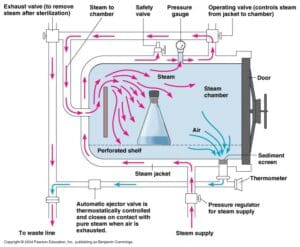

A diagram of a jacketed rectangular autoclave, illustrating the flow of steam for sterilization. Key components include the steam chamber, steam supply line, and steam jacket.

In a jacketed autoclave, the main autoclave vessel is surrounded with another pressure vessel, like a shell. That jacket can be flooded with steam or cold water to heat or cool the outside of the autoclave chamber. These can be desirable when you need faster cycle times, faster cooling times, or a drier finish. That’s especially the case with porous and textile loads. Many labs pay for these features, even if they don’t have an immediate need for accelerated cooling or dry finished loads. Bigger is better, right?

But adding those components and capabilities can give rise to new challenges. Steam jacketed autoclaves are more complex and expensive to build, and call for a great deal more maintenance. The jacket requires additional valves and controls to operate, in addition to a house steam supply or independent steam generator. Most jacketed autoclaves also require continuous water-cooling. This prevents damaging plumbing with a constant trickle of near-boiling water from the chamber. But it also means either using a large amount of fresh water to cool your effluent (literally pouring money down the drain), or getting an autoclave that has an external recirculation and cooling system.

Choosing a rectangular autoclave with an in-chamber electric heater

A rectangular autoclave with an internal heater might be a better choice for your lab. Having a visible and accessible heating element within the chamber is easier to maintain than a house supply or steam generator. Because in-chamber heating is less complex, it requires less servicing, and that servicing is less expensive.

At the same time, the rectangular chamber has larger capacity than a cylindrical vessel with the same footprint. And because a same-shaped load is a better fit, you’ll waste less of your chamber capacity if you primarily process flat trays or rectangular racks. Given the reduced maintenance and increased reliability, autoclaves with in-chamber heater jackets consistently get more done, and do so while using less water and electricity.

Many users find that a rectangular autoclave with in-chamber heating really is the “best of both worlds” for their facility. All of Priorclave’s “BASE” and “SMART” models are available in configurations with in-chamber electrical heaters, as well as all of the other options and configurations vital to academic work, research and development, and industrial tasks like quality assurance. Contact us to learn more about what kind of rectangular autoclave is the best option for your work and your lab. With a Priorclave, labs get a more reliable rectangular autoclave at a lower cost to own and operate.