Research-Grade Autoclaves: Saving Water on University Campuses

By: Priorclave Limited

Category: Uncategorized

The west coast has been experiencing record-breaking drought conditions for over three years. According to the Wall Street Journal, many of the United States’ best-loved brands (e.g., Facebook, MillerCoors, etc.) are doing their part by adopting water-saving technologies. But university and research labs can do their part, too. All too often overlooked is the extremely high water consumption of some lab equipment, principally the steam sterilizer.

Acutely aware of the high cost (monetarily, environmentally, and socially) of unchecked water consumption, several west coast universities have begun taking action to curb water consumption by addressing the extremely high water demands of the medical-grade sterilizers installed in their research labs:

- Standford University in Palo Alto, California is saving 34 million gallons of water a year by installing Water-Mizer water-conservation kits in their existing medical-grade autoclaves, minimizing water use during idle periods (Stanford Magazine, 2014).

- The University of Washington installed similar conservation kits on their medical-grade sterilizers, saving 1.6-2.4 gallons of water per sterilizer per minute.

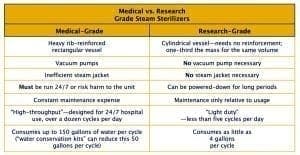

Medical Grade Autoclaves

The real problem is that these research institutions have outfitted their labs with medical-grade sterilizers. Hospitals never sleep, and neither do the sterile processing departments responsible for preparing instruments and consumables prior to surgery and treating most waste loads before they can leave the facility. Their medical-grade autoclaves are built for 24/7 operation, and outfitted with a hefty, rib-reinforced, steam-jacketed rectangular steel pressure vessel. Since the units are designed for constant operation, they cannot tolerate being regularly permitted to fully cool, or being left idle for an extended period of time. The constant steam of near-boiling water condensing from such a unit can easily damage conventional sanitary sewer systems. The solution is to cool the condensate with a constant stream of cold water – a so-called “cold water bleed.” This solution is easy to implement, but tremendously wasteful consuming no less than 1,440 gallons of water per day for each sterilizer.

This sort of water-cooling scheme is justified in a medical setting, where sterilization loads are run all day and night, and even minor infections can prove deadly. But a constant cold-water bleed on a sterilizer in a research setting – where most labs only run a cycle or two each day – is shameful, and results in almost unfathomable amounts of water being wasted. In the case of Stanford, 93,000 gallons of water was being wasted every day until they installed Water-Mizers on their research lab’s medical-grade autoclaves.

Conservation Kits

Most manufacturers of medical-grade autoclaves offer after-market water conservation kits (e.g., Water-Mizer) that are bolted onto the autoclaves. These kits include vacuum pumps to replace the Venturi-driven ejectors (another big water consumer) and “trap cooling” water conservation kits. Trap cooling kits replace the constant-flow bleeder valve with a thermocouple-controlled valve that only passes cooling water as needed, either when condensate is collected or temperatures exceed a set threshold.

Such kits minimize water waste, but do not eliminate it.

Research-Grade Autoclaves: The Most Efficient Solution

Given that most universities do not need medical-grade sterilizers, research-grade autoclaves- designed for efficiency from the ground up- are the ideal solution for these research laboratories.

Research-grade autoclaves rely on more efficient cylindrical pressure vessels. They require less time and energy to heat and cool, eliminating steam jackets, Venturi ejectors, gallon-per-minute bleeder valves, and other water-guzzling features. And labs don’t just save water, they save money. Wasting water carries a hefty price tag. For example, when installed on a metered municipal water supply, a cold-water bleed can easily run through $30 of water a day. On top of that, medical-grade sterilizers are complex devices that are challenging to operate and maintain. Research-grade autoclaves are significantly more rugged in construction and design, making for a lower lifetime cost of operation.