Affordable Research-grade Autoclaves for Scientists and Researchers

Research Autoclaves Designed for Reliability and Flexibility — at Half the Cost

Most of the steam sterilizers used in research today are based on medical-grade autoclaves. This isn’t because medical-grade autoclaves are well-suited to modern research—they are not. You’re almost certainly reading this right now because your autoclave has grown unreliable, broken down for the last time, or proved unable to run the cycles you need. These problems are a direct result of the fact that your existing autoclave was probably designed for around-the-clock hospital operation. Moving to a modern research-grade autoclave means saving money, and enjoying greater reliability and flexibility.

Most of the steam sterilizers used in research today are based on medical-grade autoclaves. This isn’t because medical-grade autoclaves are well-suited to modern research—they are not. You’re almost certainly reading this right now because your autoclave has grown unreliable, broken down for the last time, or proved unable to run the cycles you need. These problems are a direct result of the fact that your existing autoclave was probably designed for around-the-clock hospital operation. Moving to a modern research-grade autoclave means saving money, and enjoying greater reliability and flexibility.

Cost

On average most researchers only run their autoclave for a single each day, five days per week. But medical-grade sterilizers are outfitted for in-hospital use 10 to 24 hours per day, seven days per week, while meeting a very specific set of FDA criteria for medical devices.

On average most researchers only run their autoclave for a single each day, five days per week. But medical-grade sterilizers are outfitted for in-hospital use 10 to 24 hours per day, seven days per week, while meeting a very specific set of FDA criteria for medical devices.

As a result, medical-grade autoclaves have an intensive mandatory maintenance schedule, are limited in what types of cycles they can run, and cost twice as much as comparable research-grade models (with a total lifetime operating cost three to four times higher than research-grade equivalents).

Reliability

We pride ourselves on building the toughest research autoclaves on the planet. We start with a straightforward, time-tested design, with the absolute minimum number of moving parts and wear points. We build every Priorclave using standard, high-quality, easily replaced components. And we stay in touch with our customers, advising them on how to leverage the flexibility of their autoclave. The result: As of 2016, 100% of our customers have rated their Priorclave as “very satisfactory” or above—with that rating going up the longer they’ve had their Priorclave. Even Ebola researchers operating in African laboratories and prion researchers trust Priorclave to get the job done reliably.

We pride ourselves on building the toughest research autoclaves on the planet. We start with a straightforward, time-tested design, with the absolute minimum number of moving parts and wear points. We build every Priorclave using standard, high-quality, easily replaced components. And we stay in touch with our customers, advising them on how to leverage the flexibility of their autoclave. The result: As of 2016, 100% of our customers have rated their Priorclave as “very satisfactory” or above—with that rating going up the longer they’ve had their Priorclave. Even Ebola researchers operating in African laboratories and prion researchers trust Priorclave to get the job done reliably.

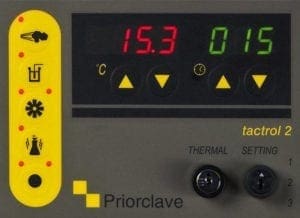

The first Priorclave steam autoclave ever built is still in operation today, thirty years later. While most manufacturers only offer a 10-year pressure vessel warranty, we guarantee ours for 20 years—and every unit we sell comes with lifetime 24/7 technical support. When issues arise, we can usually resolve them over the phone (because of our Tactrol Control System’s remote diagnostic capabilities).

You can expect a remarkably trouble-free service life from a properly specified, installed, and maintained Priorclave. And “proper maintenance” need not be arduous: Keeping the unit clean (inside and out) and regularly greasing hinges and gaskets (with supplies you can get at a hardware store) are the keys to a healthy Priorclave research-grade autoclave.

You can expect a remarkably trouble-free service life from a properly specified, installed, and maintained Priorclave. And “proper maintenance” need not be arduous: Keeping the unit clean (inside and out) and regularly greasing hinges and gaskets (with supplies you can get at a hardware store) are the keys to a healthy Priorclave research-grade autoclave.

We’re happy to consult with you on sterilization procedures and safety training to ensure that all sterilization needs are met for your project – even in the most demanding and high-risk scenarios.

Flexibility

There are a fixed set of tasks that a medical sterilizer can be expected to perform. These mostly focus on rendering clean medical instruments sterile. As a result, many such sterilizers are awful at common research tasks like media prep.

First and foremost, Priorclave autoclaves are designed for research, with a special attention to liquid loads and media prep. Our chamber and valve design discourage evaporation, bottle ruptures, and boil-over. Because we custom build each unit, any Priorclave can be outfitted with a variety of vacuum pumps, fans, and probes (both fixed and wandering). Our Tactrol Control System allows you to harness these with great precision, adjusting setpoints, hold temperatures, vacuum periods and timing, temperature ramp-up/ramp-down rates, chamber pressure, and more, with cycle times up to 999 minutes and up to 999 consecutive cycle repeats.

First and foremost, Priorclave autoclaves are designed for research, with a special attention to liquid loads and media prep. Our chamber and valve design discourage evaporation, bottle ruptures, and boil-over. Because we custom build each unit, any Priorclave can be outfitted with a variety of vacuum pumps, fans, and probes (both fixed and wandering). Our Tactrol Control System allows you to harness these with great precision, adjusting setpoints, hold temperatures, vacuum periods and timing, temperature ramp-up/ramp-down rates, chamber pressure, and more, with cycle times up to 999 minutes and up to 999 consecutive cycle repeats.