Circle Beats Square in Efficient Autoclave Design

By: Priorclave Limited

Category: Benchtop Autoclaves

Rectangular-chambered medical autoclaves were all we had in North America for decades. Designed for round-the-clock use at hospitals, the medical-grade autoclave is undeniably robust and good at what it does, sterilizing trays of surgical equipment and supplies, and making medical waste safe at all hours. But this muscle comes at a cost above and beyond the price tag of buying a new unit: Because medical-grade autoclaves are always on standby, they use enormous amounts of water and electricity to maintain their ready status. This is a totally acceptable cost in a hospital, but absurdly wasteful in a research lab.

The initial and ongoing expense of medical-grade autoclaves has often either locked labs into a big autoclave investment, forced them go with cheaper medical units that offered fewer control options, or left them using old-school “stove-top” sterilizers. Modern tabletop research-grade autoclaves offer the best of both worlds: they can run complex cycles (with repeats, custom heating/cooling ramps, etc.) and handle challenging loads, but idle cold, fully shut down over nights/weekends/holidays, and never waste a drop of water when not running a cycle.

The initial and ongoing expense of medical-grade autoclaves has often either locked labs into a big autoclave investment, forced them go with cheaper medical units that offered fewer control options, or left them using old-school “stove-top” sterilizers. Modern tabletop research-grade autoclaves offer the best of both worlds: they can run complex cycles (with repeats, custom heating/cooling ramps, etc.) and handle challenging loads, but idle cold, fully shut down over nights/weekends/holidays, and never waste a drop of water when not running a cycle.

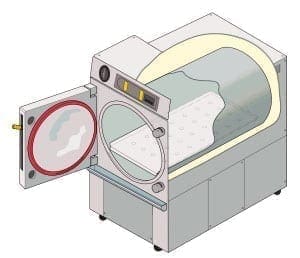

This is accomplished by harnessing the most advanced fully programmable control system to traditional cylindrical pressure chamber design. The cylindrical chamber is better suited to high pressure micro-environments, and thus requires less reinforcement and insulation, and suffers less wear and tear over the life of the autoclave than its medical-grade counterpart. They cost less to build and maintain, use significantly less energy for the same size loads as a medical-grade autoclave, and are far easier to install and service in most labs.