Priorclave Earns ASME Stamp

By: Priorclave Limited

Category: News

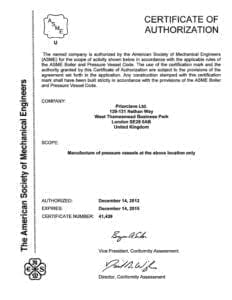

Priorclave Ltd., one of the United Kingdom’s leading manufacturers of laboratory autoclaves, is pleased to announce they have been awarded an ASME Section VIII, Division 1, “U” stamp for the manufacture of pressure vessels at their London facility. Any device bearing an American Society of Mechanical Engineers stamp has been independently verified to fully conform to the stringent design, construction, and testing standards of the ASME Boiler and Pressure Vessel Code.

According to Bernie Youngblood, President of Priorclave North America, “We’re very excited to bring these steam sterilizers to North America. Their line of research-grade autoclaves is simply unparalleled in reliability, efficiency, and suitability to research and university labs. I have no doubt Priorclave’s laboratory sterilizers will make a dramatic contribution to American biological research.”

Since 1880 the American Society of Mechanical Engineers (ASME) has worked to “promote the art, science, and practice of multidisciplinary engineering and allied sciences around the globe.” Although headquartered in New York, ASME has more than 120,000 members in 150 nations. Worldwide, ASME’s 600 technical standards are the hallmark of safety and reliability in everything from boilers and steam fittings to nuclear power facilities.

In order to earn ASME certification a manufacturer must undergo a rigorous process, during which third-party inspectors examine and verify every step in the facility’s organizational, manufacturing, and quality-assurance processes comply with the ASME Boiler and Pressure Vessel Code. In contrast to European systems, which offer blanket approval once manufacturing and design processes have been verified, the ASME certification process demands specific inspection and approval of the fabrication process for each and every pressure vessel that will ultimately bear the ASME stamp. This culminates in hydrostatic testing to empirically demonstrate the pressure vessel will perform as expected. ASME standards also require manufacturers to trace and verify that every component and base material used to make an ASME-stamped vessel satisfies ASME standards, down to each individual nut or bolt.

Tony Collins, Managing Director of Priorclave Ltd., applauds the rigors of ASME certification: “For 25 years now, we’ve offered sterilizers throughout the world. Meeting the high standards of ASME makes it possible for us to expand further into North America. I very much suspect we are now probably the best manufacturer of lab autoclave pressure vessels in Europe.”

CONTACT

Tony Collins, Managing Director

Priorclave Ltd.

129–131 Nathan Way

West Thamesmead Business Park

London SE28 0AB

United Kingdom

T +44 208 316 6620

F +44 208 855 0616