Like Water for Chocolate: The Role of Steam Sterilisers in Cocoa Bean Processing

By: Priorclave

Category: Steam Autoclaves

People are often surprised to learn that steam sterilisers play any role in chocolate production. But the fact is, making chocolate is a bit more disgusting than you’d expect. The raw cocoa that goes into chocolate doesn’t start out as picturesque beans like the above.

One of the first steps on the extremely long and complex journey from raw cocoa bean to chocolate bar is fermentation:

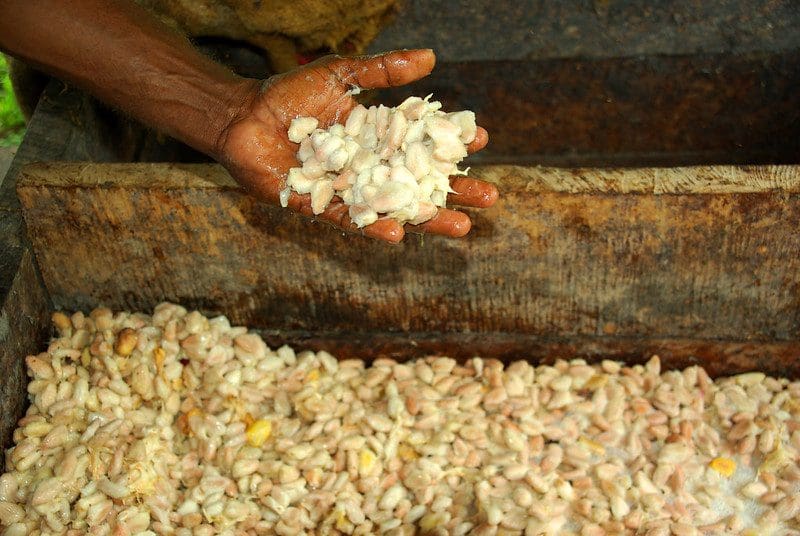

Cocoa farmer holding fermenting cocoa beans.

The “white” cocoa beans (which are the cocoa seeds found in the iconic cocoa pod, still encased in the pulpy fruit of the cocoa plant) are separated and heaped in piles or wooden fermenting boxes. Then, bacteria breaks down the fruit and seed. This process is a key step in creating chocolate’s distinctive color, aroma, and flavor. (Although, at this stage, that flavor is still fairly subtle and somewhat bitter.)

Without fermentation, chocolate won’t taste like chocolate. Fermentation—and the drying step that follow—are the primary factors in the quality of the resulting cocoa powder and thus the resulting chocolate.

That fermentation process relies on yeasts, lactic acid bacteria, and acetic acid bacteria and makes excellent conditions for a wide range of other bacteria, as well as fungi, molds, and other potential pathogens. The drying process may reduce this somewhat, but the resulting raw cocoa beans—which look delicious—are fairly well contaminated. Much of that is harmless bacterial strains present in many foods, such as bear, kimchi, and sauerkraut. But raw cocoa beans also carry potentially dangerous loads of e. coli, Salmonella, and other dangerous pathogens.

After drying, the beans are bagged and shipped—warm, humid, anaerobic conditions that are nearly ideal for many bacteria to flourish.

The Steam Steriliser’s Dual Role in Chocolate Making

Once cocoa beans reach the chocolate factory, they are roasted. Roasting greatly reduces the bacteriological load on the beans. It’s often sufficient to render the beans food-safe during home processing or in small boutique operations. But roasting isn’t intended to sterilise the beans and doesn’t reliably do so. Relying on roasting alone at an industrial scale is a risky proposition.

In order to ensure food safety, industrial chocolate makers use a specialised steam sterilising autoclave (usually just after roasting). Not only does the autoclaving reliably kill off all the pathogens that have taken up residence on the raw beans, but it can also improve the beans’ color and flavor.

Adding a steam steriliser step to cocoa processing also improves chocolate yields by simplifying further processing steps. The heat and pressure of the steam steriliser make the beans’ shells “puff up” and loosen. They are then easier to remove, which preserves more of the chocolate nib and eases later breaking and winnowing steps.

But that’s not the only role steam sterilisers play in getting you your candy bar. At Priorclave, we’ve had long working relationships with a variety of food processors, including Nestlé. In food and beverage research and development we’ve learned that autoclaves often need to serve double-duty. They must perform both standard lab tasks (like processing waste loads, media prep, and sterilising glassware), as well as emulate the performance of the steam sterilisers, autoclaves, and retorts used in food production.

Steam Sterilisers for Food Development and Production

Recently, we’ve been working with a major chocolate maker looking for a lab autoclave to use for “debacterising” raw cocoa beans prior to processing in their R&D environment. In this case, they needed something a little beyond the normal R&D setup or chocolate processing line.

They were looking for a “clean room”-like setup with a double-ended autoclave that could process loads of five to 150 kilograms (10 to 300 lbs) of raw cocoa beans in one pass, taking them from a “dirty” zone into a “clean” zone suitable for food production.

Unfortunately, all too often, food labs end up with an autoclave that fails to meet their needs for both reliability and flexibility. For example, they’ll get sold a large jacketed steriliser originally designed and developed for medical applications. These are a poor fit for product development, especially in food and beverage. They’re expensive, consume a tremendous amount of resources, and are labor-intensive to maintain. Additionally, they often lack the programming capacity needed to emulate food production processes.

“This is why we’re so invested in having a real conversation with every facility looking to invest in a new large autoclave, especially in food and beverage,” explains Barbra Wells, president and CEO of Priorclave North America. “I’d much rather sell someone less autoclave that makes them happier—or even direct them to a totally different solution—than cash in now and make someone’s workday miserable for the next decade.”

Looking for an appropriate steam steriliser to develop your next pantry staple or tasty treat? Let’s discuss what your really need to get your work done.

photo credits

- [credit: “Cocoa farmer David Kebu Jnr holding the finished product, dried cocoa beans ready for export.” by DFAT photo library is licensed under CC BY 2.0.]

- [credit: “Cocoa farmer David Kebu Jnr holding fermenting cocoa beans.” by DFAT photo library is licensed under CC BY 2.0.]