The autoclaves used in most labs and universities are finicky, waste water, and run up huge power bills. But that’s because they’ve been optimized for medical applications that demand extremely high throughput and short cycle times. This comes at the cost of durability, reliability, and efficiency.

Unlike other autoclave manufacturers, Priorclave doesn’t try to sell the same one-size-fits-all medical-grade autoclave to every hospital, university, and factory. From experience, we know that these facilities—and the work that goes on inside them—all have very different requirements. That’s why we listen to understand your needs first. And then we outfit you with a purpose-built autoclave that does what you need it to and not what you don’t.

Priorclave autoclaves won’t get in your way, break down all the time, or waste your resources. They’re designed and built to meet your needs, not someone else’s.

By switching to a purpose-built autoclave, your lab will greatly reduce its environmental impact, using less energy and water—about 1/6th to 1/10th as much water and energy as comparable general-use models. And a purpose-built autoclave has a significantly lower initial purchase price, with much lower ongoing maintenance costs.

How Does a Steam-Jacketed Autoclave Function?

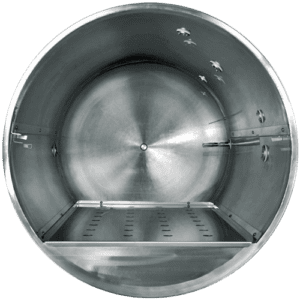

Every autoclave uses heat to sterilize loads by flooding a sealed pressure chamber with steam and holding the load at a specific temperature for a given period of time. This combination of moist heat, sustained high temperature, increased chamber pressure, and time will consistently kill bacteria and other microorganisms, deactivate spores and viruses, disinfect pathogenic waste, and sterilize culture media, pipette tips, glassware, surgical instruments, and the like.

Many modern steam sterilizers—especially larger models—rely on a “jacketed” design to speed up this process. These units require an independent steam generator. That steam is first sent to the “steam jacket,” which is a rectangular steel shell surrounding the rectangular pressure chamber, in essence “pre-heating” the chamber. Then the chamber itself is flooded with steam. This nested arrangement makes it possible to reach the sterilization temperature relatively quickly. At the end of the sterilization cycle, the jacket can then be flooded with cold water to likewise speed cooling.

Under normal operating conditions, standard jacketed autoclaves tend to require more water, using constant flow “bleeder valves” to cool outflow. When the steam sterilizer is constantly running back-to-back cycles, that process is vital. But if your lab averages just one to three daily cycles, you don’t need those bleeder valves cooling your machine 24/7.

Nevertheless, many labs still buy these standard jacketed models because they need some function or feature they provide—a rectangular chamber, a certain volume, a cooling jacket—and are led to believe that they must go with a full steam-jacketed behemoth with every bell and whistle in order to get what they need. But they don’t. And it’s costing them.

The Hidden Cost of the Wrong Autoclave: High Water Consumption

The University of Alabama-Birmingham houses hundreds of labs in its 10 schools and 24 research centers. Most of these use steam-jacketed autoclaves, even though their applications did not necessarily demand this feature. In fall 2023,

UAB studied the environmental and monetary costs of using jacketedsteam sterilizers in their labs and found that their jacketed autoclaves used around 150 litres of water per cycle. Meanwhile, similarly sized and tasked purpose-built non-jacketed autoclaves used less than 8 litres per cycle. When UAB analysts estimated the associated water costs, they found that those steam-jackets were costing them an extra $74,000 per year.

This is not a new problem, nor one limited to a single organization. During a 2008 audit, Stanford University analyzed 60 of its

jacketed autoclaves. They were consuming more than 352,000 litres of water per day—or 3 percent of the university’s entire daily water ration. In a 2016 autoclave audit, the University of California-Riverside (UCR) found similar levels of water waste. During one notable 39 day period, two UCR autoclaves used almost 61,000 litres of water, even though neither ran a single cycle!

Compare this water consumption to Priorclave’s purpose-built autoclaves. A comparable Priorclave autoclave installed alongside UCR’s existing jacketed units used just 15 litres of water per cycle, and used no water while sitting idle.

The jacketed design isn’t inherently to blame. The problem comes when the autoclave isn’t designed for the work it’s actually doing.

Choosing the right options for your lab can have a real impact on the bottom line, while still retaining all the core autoclave functions you need. At the University of York, for example, they replaced an existing jacketed rectangular steam autoclave with a slightly larger, purpose-built Priorclave jacketed rectangular autoclave. This reduced their running costs by 56%, including an almost 90% reduction in the cost of water supply and disposal and a 92% reduction in water softener salt consumption.

Higher Energy Efficiency, Smaller Carbon Footprint

Most labs and manufacturers worry about their energy consumption and its effect on their carbon footprint. As more and more labs lead decarbonization and sustainability efforts within their organizations, the pressure to “right-size” your steam sterilizers grows.

Meanwhile, most jacketed autoclaves are still designed to “idle hot”: in order to deliver shorter cycle times, they maintain a head of steam even when no cycle is running. As part of the 2016 UCR audit, analysts tracked energy consumption. Their existing jacketed autoclaves varied from 11 Kwh/day when idle to 222 kWh/day during high-usage periods. On average, their jacketed autoclaves used around 84 kWh/day. By comparison, UCR’s purpose-built Priorclave autoclave—which produces steam only on demand—averaged just 15 kWh/day. (For details on how chamber shape drives autoclave power consumption, please download our full “Autoclave Energy Consumption” whitepaper.)

Given their high demand for steam, many facilities choose to run their jacketed autoclaves off of house steam supplies. This steam is almost invariably generated by burning natural gas, resulting in carbon emissions of about 2.4 pounds of CO2 per sterilization cycle. But the in-chamber steam generation of purpose-built autoclaves relies on electrical heaters, which can be powered by low-carbon or zero-carbon sources. Among Priorclave’s most popular models is the EH320, a 320-liter purpose-built steam sterilizer. It will save that lab around 326,000 litres of water and 18,200 kWh of electricity over a comparably sized jacketed autoclave.

Purpose-Built Autoclaves for Any Use

A purpose-built autoclave will always outperform a standard one over time. It’s more efficient, experiences less downtime with fewer repairs, is less costly to maintain, and drives lower utility costs. Priorclave UK offers the full range of autoclave styles:

- purpose-built cylindrical autoclaves with in-chamber heaters

- purpose-built cylindrical autoclaves that can run off of independent steam generators or house steam

- jacketed rectangular autoclaves that can run off of independent steam generators or house steam

- purpose-built rectangular autoclaves with in-chamber heaters, including programmable units 350L and larger (few manufacturers offer these)

- rectangular autoclaves with in-chamber heaters and cooling jackets for the greatest efficiency in a fast-cooling rectangular autoclave

No other autoclave manufacturer offers as many options or customizations to get your lab exactly the functions it needs without wasting resources on features that do the job someone else needs done.

Let’s talk about what kind of autoclave your lab needs and then we’ll get to work building the right one for you.