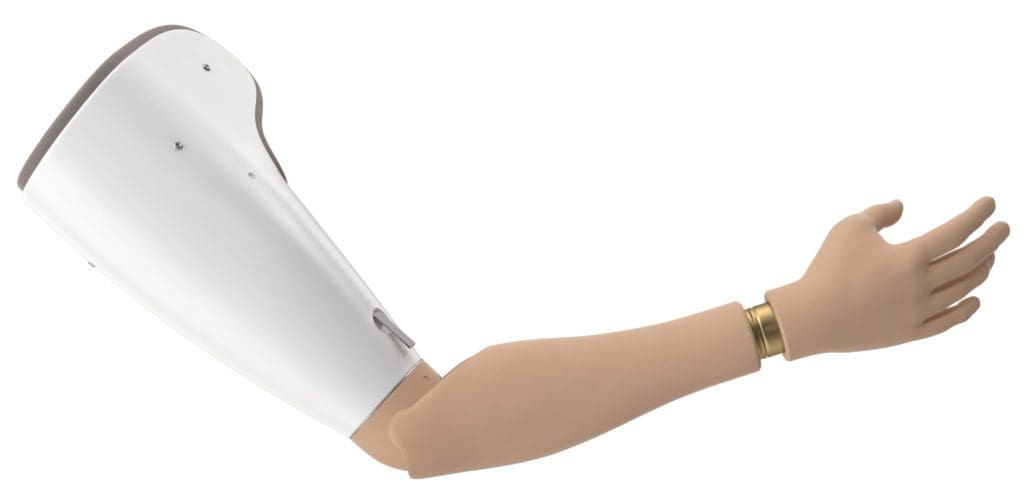

When designing prosthetics and other medical devices, engineers must feel confident that the device will remain reliable and perform correctly over the course of years. As such, prosthetics and devices undergo accelerated aging or life cycle tests in autoclaves to simulate the passing of time before these products are made available to patients.

Of course, in a medical setting, all prosthetic components and implants are cleaned, disinfected, and sterilised before every use. But in a laboratory setting, autoclaves are instead used for testing device prototypes. The heat and pressure inside an autoclave serve as the perfect atmosphere for evaluating the long-term performance, safety, and stability of medical prosthetics that will eventually be used inside the body.

Biomedical research and development labs rely heavily on dependable and efficient autoclaves. Our research-grade sterilisers are optimised for daily prototyping and durability testing, subjecting your prototypes to the same stress and strain as a medical-grade steriliser – but without the high costs of maintenance and operation.

Understanding how the prosthetic or medical device is strained during an accelerated aging test will help determine when it may need to be removed from service or if it should be used at all. For example, the material could begin to break down, experience deformation or cracking before it was initially estimated to do so. Proper testing can help avoid potentially dangerous scenarios such as this.

Accelerated aging and life cycle tests are performed on prototypes of both reusable and non-reusable medical devices during the product development process. Identifying what you will be testing is key in determining the appropriate parameters for your test. Metal materials vs. non-metal materials or single components vs. multi-component assemblies are two common variables which will help determine the pressure, temperature, and time parameters of an accelerated aging test. Our team is knowledgeable in this industry and can answer your questions regarding the autoclave you need for a given load type.

Complex life cycle tests for prosthetics and medical devices are facilitated by Priorclave’s Tactrol Control System, programmable to whatever length cycle you need (up to 999 hours and/or repetitions). Your lab will also use substantially less water and energy with our autoclaves, which provide efficiency advantages over medical autoclaves intended for hospital settings. In addition, there are options to customize the temperature and pressure ramps, dwell times, add monitoring, and more. Our custom features include load-sensed process timing, combined pre-cycle vacuum, and post-cycle vacuum drying. Finding which autoclave is suitable for you will depend on volume, capacity, speed, and available space.

Priorclave has a dedicated team of seasoned experts ready to guide your autoclave purchasing decision, even if you are unsure about your specific needs. For example, you might feel uncertain about precisely what autoclave features and functions are appropriate for testing prosthetics and medical devices in your lab. We can help you find the right autoclave, whether it’s one we have ready to go or a custom autoclave built specifically for your lab.