Bioreactors and fermentors are vessels that facilitate biochemical reactions by providing the optimal conditions for those reactions. In order to prevent contamination, it’s vital that you have a reliable method to properly sterilise these vessels between uses.

But reusable fermentors and bioreactors pose some sterilisation challenges. They are usually made of a combination of materials (including stainless steel, glass, and several different types of plastic). They come in a range of configurations and sizes. Their structure and weight often demand extra sterilisation steps or specific steriliser features. For example, ATF (Alternating Tangential Flow) bioreactors require gradual increases in temperature and pressure to reliably sterilise their hollow fibre filters. Not all autoclaves make it easy (or even possible) to customise these temperature and pressure ramps on a per-cycle basis.

The primary concern when sterilising bioreactors and fermentors is avoiding air pockets within the fermentor’s vessel (sometimes also called the “reactor tank”). To ensure proper sterilisation, it is essential that steam make contact with every surface of the bioreactor, especially within the vessel (which poses the greatest risk of harbouring contaminants). When the bioreactor vessel traps air, it prevents steam from completely sterilising the device. This is especially an issue when sterilising a bioreactor/fermentor using an autoclave that relies solely on “gravity cycles.”

If you regularly must sterilise fermentors or bioreactors, then you need an autoclave that can run what are known as “pre-vac” cycles. Such autoclaves are outfitted with a vacuum pump that allows them to draw a partial vacuum in the chamber during the initial heating period (while the chamber is being flooded with steam). By “pulsing” this vacuum, the autoclave can reliably ensure that the cold air is entirely removed from the autoclave chamber (even when processing loads and vessels that are especially good at trapping air).

Priorclave offers pre-vac capabilities as an option on every autoclave model and can further customise any model to handle specific load types. Our custom autoclaves come with programmable features to fit most sterilising needs. These features include load sensed process timing, pulsed free-steaming, and various combinations of pre-cycle and post-cycle vacuum operation (which, in addition to ensuring sterilisation, can also help produce dryer loads or speed cycle times, depending on your application).

Finding which features are right for you will depend on the items being processed, load density, desired cycle speed, and lab space. Here are our top recommendations for sterilising fermentors and bioreactors:

- A top-loading autoclave is ideal for tall flasks, fermentors, and bioreactors in a modern laboratory setting. Top-loaders offer maximum height while taking up minimal floor space (making them our top sellers in many research areas). Like all of our autoclaves, they feature our proprietary Tactrol Control System, which makes it easy to create custom cycles while retaining “one-touch” load-and-go simplicity.

- Our pass-through autoclaves provide a sterile path in and out of sealed laboratories. Every Priorclave double-ended autoclave includes advanced safety features such as door interlocks, which reduce the potential for laboratory standards being compromised. This may be ideal for a large bioreactor or fermentor, or certain sensitive research activities.

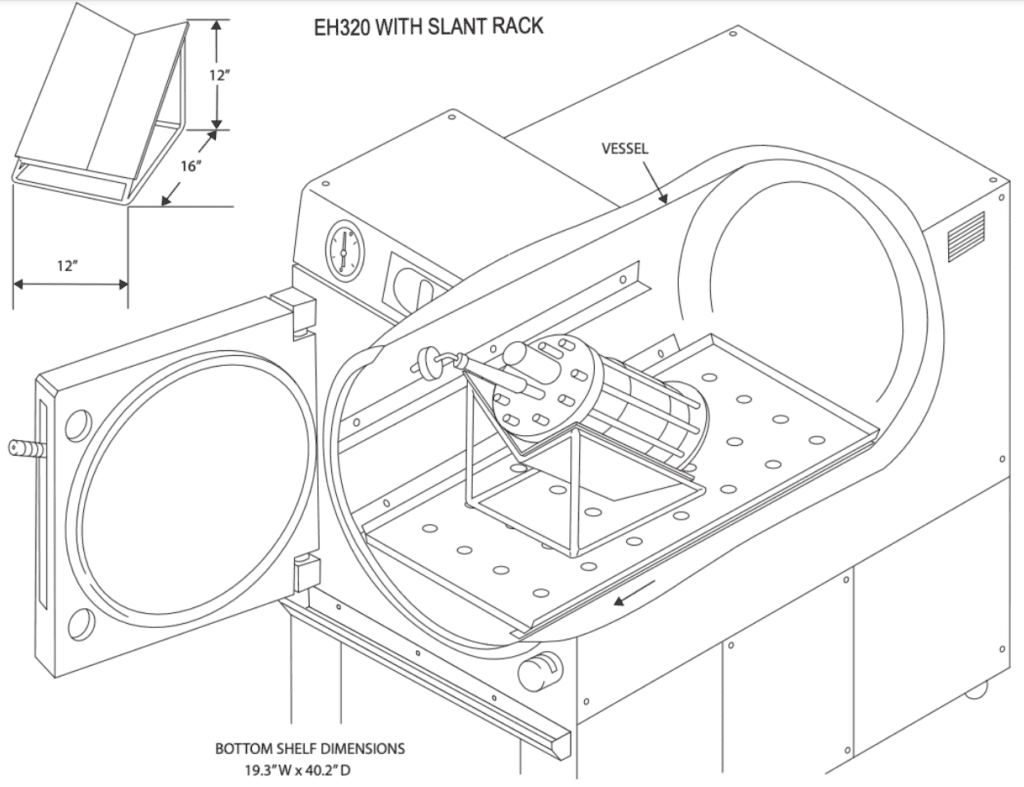

- Priorclave offers tilt racks and other accessories to help labs expand the capabilities of their autoclave and accommodate a wider range of load types. For example, with a proper slant rack, our standard 320L front-loading autoclave can hold a bioreactor over 30 inches tall. (Without a tilt rack, such a unit would only accommodate fermentors under 19 inches.)

As there are many different types of bioreactors, consulting with an autoclave specialist is the best first step. Priorclave has a team of seasoned experts ready to guide your autoclave decision if you are unsure of your specific needs. For example, if you are uncertain about the appropriate autoclave size for your instrument or if you have any questions about which sterilisation cycle to use for your specific type of bioreactor, we are here to help.