Do All Steam Autoclaves Really Need a Steam Jacket?

By: Priorclave North America

Categories: Lab Autoclaves Steam Autoclaves

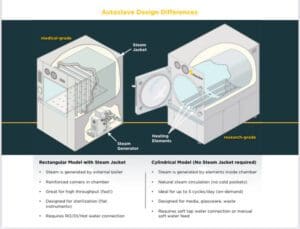

Until fairly recently, North American labs haven’t had a lot of options when it comes to standalone steam autoclaves. Your choice was steam jacket or nothing. Jacketed machines are great for high-throughput sterilization, and they process dry loads quickly (by autoclave standards). But there is a steep trade-off:

In order to get fast cycle times required in hospitals or pharmaceutical production, “medical-grade” steam autoclaves depend on a complex and expensive “jacketed” design. Jacketed autoclaves consume a lot of electricity, an enormous amount of water, and can be tricky to properly maintain.

Terminal sterilization labs can benefit from a jacketed autoclave, making the added expense worthwhile. Fortunately, studies indicate that most research labs focus on less demanding applications. They can safely opt for a non-jacketed autoclave. These are designed from the start for highly efficient operation without a steam jacket. That greatly improves your energy use. It’s also significantly easier on your budget and can revolutionize your workflow and ergonomic lab layout.

Do You Need a Steam Jacket?

Plenty of labs might require an autoclave that’s running or ready to run 24/7/365. Hospitals, pharmaceutical manufacturers, and some production facilities have similarly high throughout. They either

- constantly sterilize large loads

- need those loads done as quickly as possible

- need to have them come out of the chamber as dry as possible

Or a combination of all three. In such situations, a “steam jacketed” autoclave is a must. Such a sterilizer generates its steam in a separate chamber. It can then flood both the jacket and sterilization vessel with steam (for faster heating and sterilization). After the cycle, it can vent the chamber while flooding the jacket with cold water. This speeds cooling and encourages evaporation (resulting in drier loads).

But what if that’s not your business? Most university or other research labs don’t have very high throughput. The majority run just a few loads each day, at most. Most research labs autoclave plastics, media, waste, wet and dry loads with no rush to clear the autoclave. Natural cooling and drying work best for them. If you’re doing destruction testing, you may be keeping your autoclave sealed and hot for dozens of consecutive cycles. Rapid cooling is not an issue. And if you’re running liquid loads, fast-cooling can be disastrous.

A Steam Autoclave for the Rest of Us

Working with research labs over the years, we’ve found that most university labs typically run about 3 cycles per weekday. That simply doesn’t warrant the expense and resource consumption of a jacketed autoclave. Depending on your load types, Priorclave autoclaves can run between one and six cycles per eight-hour workday. These sterilizers generate steam right in the chamber using submerged electric heating elements and cool naturally. This approach is extremely efficient, highly sustainable, and cost-effective (the savings in maintenance costs alone are substantial for many labs).

If you don’t need your autoclave heating and cooling your loads as fast as possible all day long, then a non-jacketed research-grade autoclave should meet your needs. In fact, Priorclave’s autoclaves represent such a cost savings that if you need more cycles per day, you can usually afford two of our machines for the price of a single jacketed autoclave. Even then, you’ll still use less water and electricity than you would with that single medical-grade, steam-jacketed model.