Priorclave CEO Challenges Steam Autoclave Manufacturers to “Come Clean!”

By: Priorclave North America

Categories: Lab Practices Steam Autoclaves

The steam autoclave has long been the workhorse for hospitals, pharmaceutical companies, and research labs. But it’s long overdue for a sustainability update. At the My Green Lab 2021 Sustainability Summit, Priorclave CEO Barbra Wells discussed what Priorclave North America is doing about it—and issued a challenge to the autoclave competition in the research space: “We want autoclave manufacturers…to come clean!”

The Most Sustainable Steam Autoclave in North America—with the Label to Prove It

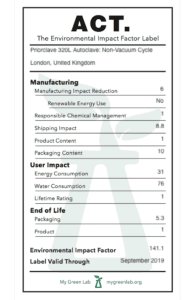

Priorclave was the first steam autoclave manufacturer in the world to carry My Green Lab’s ACT (Accountability, Consistency, and Transparency) Label. And it has been a key to its growth in North America since 2017. Priorclave has been hand-building steam autoclaves in London since 1988; we’re not new, but we’ve brought new choices to the North American market. That’s because, before Priorclave, the only autoclaves on the market here were medical-grade autoclaves.

Priorclave only produces research-grade autoclaves—and the difference is especially significant when it comes to sustainability. In fact, the sustainability of Priorclave’s research grade product makes such a difference that our customers in nearly every sector have cited the ACT Label as a reason for selecting our autoclaves over our competitors’.

On-Demand Makes the Difference

Why do Priorclave steam autoclaves consistently come out on top when you compare their environmental impact with that of competitors? Traditionally, stateside autoclaves have been jacketed-—meaning they remain hot and ready to run at all times. While that may be necessary in hospitals, it’s just not necessary in research and quality control labs. In these settings an autoclave may only need to run a few cycles a day. But an autoclave designed for 24/7/365 operation cannot be run on an “as-needed” basis. As a result, medical-grade autoclaves in research settings use tens of thousands of kilowatt hours more than non-jacketed research autoclaves. On top of that, they waste half a million gallons of fresh water per year, per autoclave—just standing by!

Priorclave’s steam autoclaves, by contrast, work on demand. They consume no electricity or water unless they’re actually running a cycle. In part thanks to My Green Lab’s ACT Label, Priorclave has been able to quantify the difference between their steam autoclaves’ energy use and their competitors—and it’s major: a single small medical grade autoclave, for instance, uses as much electric as 100+ computer monitors running at all times.

Just a Jumping Off Point for Growing Greener

Because the comparative sustainability of Priorclave’s steam autoclaves has proven so consistently important to our customers—many of whom participate in a green lab program, Living Building Challenge, or other environmental initiatives—we’ve taken further steps to get greener. We’ve switched to biodegradable packaging and carbon-offset shipping, and an end-of-life buy back program is on the horizon.

So maybe that’s why our competitors haven’t yet stepped up to the challenge and “come clean”: when it comes to sustainability in a research setting, they just can’t measure up.

(You can watch the full presentation by Priorclave North America CEO Barbra Wells online now.)