Building Infrastructure, Unpleasant Surprises, and the Hidden Costs of Buying New Autoclaves

By: Priorclave North America

Categories: Lab Autoclaves Lab Design Lab Practices

As you compare autoclaves for your lab, you may find some manufacturers are quoting prices that seem extremely attractive. This is especially the case when you factor in recent supply chain and shipping issues , which have driven up the costs of so many lab supplies and other goods.

Unfortunately, we’re increasingly hearing that many of these quoted prices bring with them unpleasant surprises. Customers belatedly discovered that the quote doesn’t include items needed to make the autoclave work. Sometimes these are relatively small items (like “water saver” add-ons). While such “a la carte method” of pricing is annoying, it’s rarely too painful. What becomes agonizing is discovering late in the game that the autoclave will require atypical infrastructure to be in place before their machines will work. Adding that infrastructure can be potentially costly (adding hundreds to thousands of dollars to the price you’re really paying). It’s invariably time-consuming—and extremely frustrating, given that it is often unexpected.

Priorclave CEO Barbra Wells is outspoken on the subject of hidden costs. “If the manufacturer isn’t upfront about the real cost of getting that autoclave up and running, there is really no chance that the average administrator is going to be able to accurately foresee the real expense of setting up those systems. The labs think they’re getting a good deal, but they end up with less budget for their actual research.”

Autoclaves that Waste Resources (and other Unpleasant Surprises)

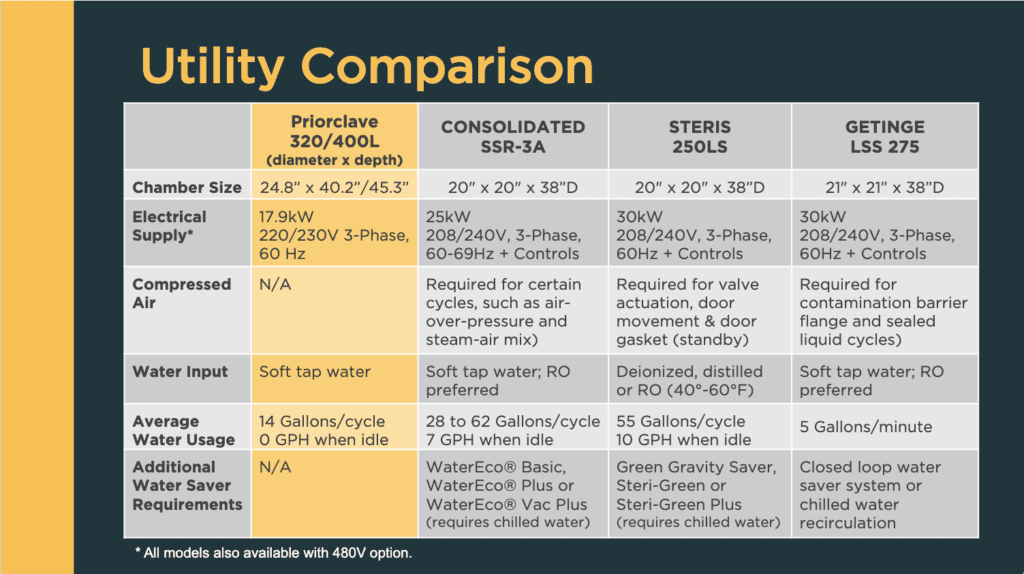

The biggest hidden costs have to do with water supplies and resource consumption. For example, most competitors’ autoclaves “prefer” (i.e., require) reverse osmosis (RO) treated water. RO filtration systems are expensive to install and run. But very few research or QA labs actually need RO water. (It’s not needed for sterilization or product testing. RO water is required for pharmaceutical production and other similar terminal applications.)

The expense of installing and maintaining an RO system is further multiplied because of the large amount of water consumed by jacketed autoclaves (which are the “standard” autoclaves sold by many manufacturers). Jacketed autoclaves use tens to hundreds of gallons of water per cycle, plus 5 to 10 gallons per hour when sitting idle. Feeding such an autoclave RO water requires a filtration system that, by itself, could case tens of thousands of dollars to purchase and install.

But the expense doesn’t stop there. Reverse osmosis water systems waste between 3 and 20 times as much water as they produce. “It takes five gallons of water to make a single gallon of RO water,” observes Wells. “It’s an environmental nightmare by itself. Meanwhile, an increasing number of labs and facilities are approaching us because they are having to deal with the potential for water shortages and rising costs.”

Other manufacturers require their autoclaves be fed pre-heated or deionized (“DI”) water—adding further to both upfront setup expenses and recurring utility and maintenance costs.

No-nonsense Autoclaves for Labs

Priorclave autoclaves are built for no-nonsense use and maintenance, without escalating installation add-ons and costly ongoing expenses. They were designed and built to run in the widest range of environments (including remote facilities in the developing world). As a result, many models are largely plug-and-play . Some don’t even require dedicated plumbing.

Tired of wondering whether you’re getting the best information or a good deal? Reach out to Priorclave now to discuss your options. We’ll be as cost-transparent as we can be with the information we have—and what we don’t know, we’ll help you find out.