Lab Design Disasters: Four Surprisingly Common Unasked Questions about Autoclave Placement

By: Priorclave North America

Category: Lab Design

We trust that all four of these autoclave installation questions will seem glaringly obvious—once you see them written out. But it’s been our experience that all too often autoclave buyers either fail to consider these questions, or brush them aside instead of giving them careful consideration. That often results in misery for all involved.

Question #1: Do We Need a Drain?

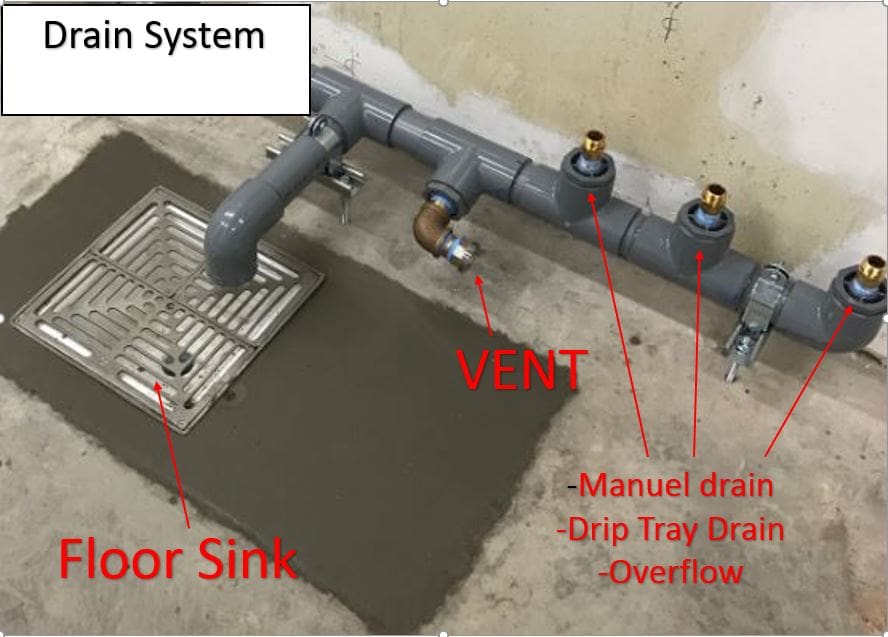

The answer seems obvious: Any machine that takes water in needs somewhere for that water to go when it’s done. It’s true that it’s fine to drain some smaller benchtop autoclaves into a wastewater jug that you periodically dump down the drain. But for most larger units, under most use cases, you’ll need a proper floor drain.

The more common issue is that the drainage system in your lab may not be able to handle the high temperatures of the wastewater and steam leaving the autoclave chamber.

Under some operating conditions and in certain drain systems, the temperature at the drain line can be as high as 136ºC (270ºF). That’s nearly twice the rating for prolonged heat exposure in PVC plumbing. Even some heavy-duty chemical resistant plastic plumbing systems designed for labs, like Vulcathene , are only designed to withstand habitual exposure to 100°C water. And the materials used to seal the joints in drain systems may be somewhat less heat resistant than the plumbing itself.

There are several options to mitigate the potential for heat damaging your drains. All of them are fairly simple, and extremely cost effective—especially compared to the expense of repairing a sanitary sewer line leak in a poured concrete floor.

Question #2: Will This Thing Get Hot?

Obviously, you know the autoclave will get hot; that’s what you’re paying it to do. Nonetheless, when deciding how to lay out their facility, many people fail to take into account the fact that the autoclave vents steam that is hot and moist. They then install it right next to an ice machine or ultra low temperature (ULT) freezer or other equipment and supplies that are sensitive to heat or moisture.

“A lot of the time,” Priorclave Managing Director Tony Collins notes, “they just stick the autoclave in a little room off the side, and it makes it like a Turkish bath in there.”

This tends to have grave repercussions for the cabinets and drywall:

Question #3: Will it Ever Need Maintenance or Repairs?

Priorclave makes a notably reliable and low-maintenance autoclave—but it should be regularly maintained, and will occasionally need a repair. That means someone needs to be able to access all sides of the unit to remove the panels. We recommend an absolute minimum service clearance of 18 inches on each side, and at least 12 inches of clearance at the rear. This clearance also prevents issues with heat or moisture adding wear and tear to neighboring equipment or walls, and makes it much easier to have a proper floor drain, plus any extra equipment needed to cool or condition wastewater leaving the chamber.

Every autoclave installation includes leveling the sterilizer on its integrated legs, to ensure proper drainage. If the autoclave has to be pulled out of a tight niche each time you want to access the panels or pipework, it will also need to be re-leveled once you’re finished, adding extra work (or, more often, a step that gets skipped, causing further issues down the road).

Question #4: Are We Planning to Use This Thing?

As you are no doubt well aware, you must place items inside the autoclave if you wish to sterilize them. Nonetheless, we occasionally get buyers who don’t plan ahead. They plan to put their autoclave into a space where there isn’t enough room to open the door, or enough space to practically load or unload it.

As Priorclave Sales Director Lee Oakley recalls, “One of our customers purchased a very large 700 liter autoclave and did not leave enough room for a loading trolley.” Presumably their intent was to load their autoclave bucket-brigade style, which is an excellent team-building innovation, but might prove tedious over the autoclave’s multi-decade service life.

Want to Get Your Lab Layout Right?

As Lee often notes, “If your site survey is done correctly, none of this should be an issue.” We’re pleased to offer exhaustive documentation to walk you through this process. Or you can just give us a call and talk it through.