Energy Efficiency and Cylindrical Autoclaves

By: Priorclave North America

Category: Lab Design

This past spring, a 2020 article in Labmate Online came to our attention: “Energy Efficient Autoclaves —Misconceptions and Misunderstanding.”

Owing to our longstanding interest in energy efficient autoclaves and sustainable labs, we eagerly clicked. We found a good presentation of the fundamentals of steam sterilization. But our experience differs from the author’s conclusions.

We All Agree on the Fundamentals

If you are looking for a solid discussion of the basic foundations of steam sterilization and steam generation, this article has that. And we couldn’t agree more with the following statement:

“A failed sterilization cycle is the greatest potential source of wasted energy, effectively doubling power consumption by necessitating a repeat cycle.”

Amen! Autoclave reliability is fundamental. In fact, this is among the most common reasons our customers cite for switching to a Priorclave:

Their previous autoclave had proven unreliable

But from there, we part ways with this article. This ultimate claim is that a heavy-chambered, jacketed rectangular autoclave will be more efficient than a comparable cylindrical autoclave. The author offers two reasons:

- A heavy chamber is better at retaining heat. This will hypothetically make it more reliable at successfully sterilizing its loads, because it will more easily maintain sterilizing temperatures.

- When comparing front-loading sterilizers, a rectangular pressure vessel is usually easier to load efficiently. With less wasted space, you use less energy per sterilized item.

These are both interesting hypotheticals.

But they don’t reflect reality.

Real-world side-by-side trials have shown the opposite is true:

Light-weight cylindrical chambered autoclaves consistently outperform comparable jacketed rectangular-chambered models.

Energy Efficient Autoclaves: Strong Evidence for Cylindrical Autoclave Efficiency

In 2016 the University of California (Riverside) replaced one of their existing jacketed rectangular autoclaves with a comparable cylindrical unit. (That is, they selected a somewhat larger cylindrical autoclave, so that the two units would be able to sterilize similar sized loads. As the article correctly points out, a cylindrical chambered autoclave needs to be larger in order to process the same sized load.)

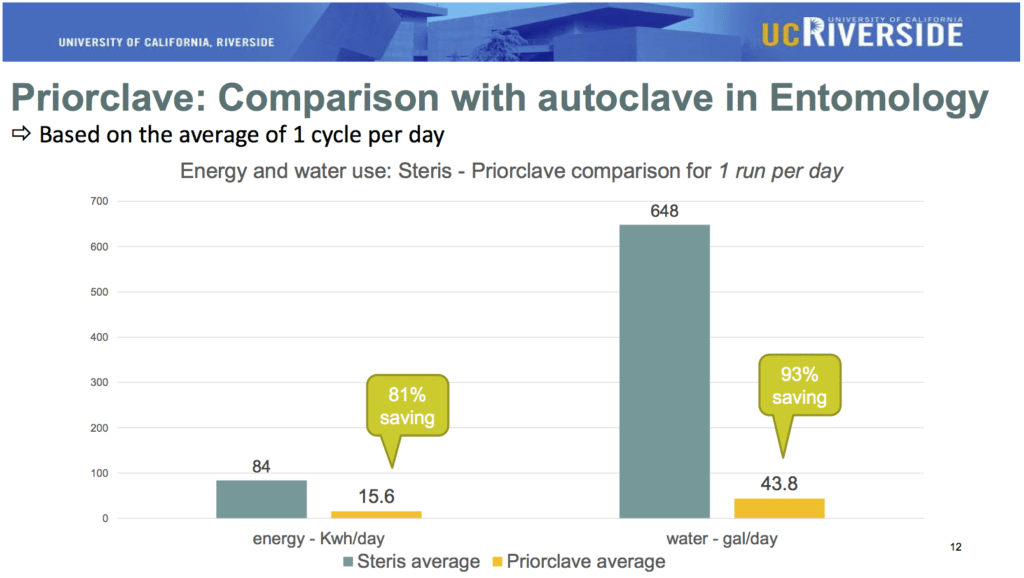

In the first 26 weeks of their test, UC-Riverside found that the non-jacketed cylindrical unit used 81 percent less energy and 93 percent less water than a comparable jacketed rectangular model. Over the next ten months they found that the cylindrical autoclave ultimately used 83% less energy than the rectangular model. It also used 97% less water.

rectangular vs. cylindrical autoclave energy & water consumption

Most importantly, in UC Riverside’s study, the two autoclaves performed with equal effectiveness—neither failed loads more often. But, given the massive difference in resource consumption, even if sterilization cycles in the cylindrical autoclave failed 75% of the time, it would still be more energy efficient than its jacketed rectangular counterpart.

Anecdotally, it seems that rectangular chambered autoclaves may fail sterilization more often in the field—at least according to what we’ve heard from labs. In part this is due to fluid dynamics and the vessel shape itself: anyone who has cleaned a fish tank and a fish bowl has noticed that rectangular containers have poor fluid circulation, and corners tend to accumulate crud. But the bigger issue often comes down to user error among less-experienced lab techs. A rectangular vessel autoclave is indeed easier to load—which also means it’s easier to overload. This exacerbates the steam circulation issues inherent in a rectangular chamber, leading to “cold pockets” where the load never reaches 121ºC.