Choosing the Right Autoclave for Bioreactor Sterilization

By: Priorclave North America

Category: Lab Design

Bioreactors are the workhorses of many labs, creating the ideal controlled environments for cultivating cells, fermentation, regulating biochemical reactions, and the like. But between experiments, this device needs thorough sterilization to prevent contamination. Reusable bioreactors present unique sterilization challenges that demand careful consideration and the right equipment.

Bioreactors are Porous Loads—and Tricky to Sterilize

Bioreactors are complex, which makes them tough to reliably clean. It isn’t simply that they can be constructed from a variety of materials—stainless steel, glass, and different types of plastics—but they also have many nooks, crannies, and narrow passages. This makes your bioreactor a classic “porous load.”

“Porous loads” is a category that encompasses a range of materials, such textiles, narrow plastic tubes, oddly shaped vessels, and many waste loads. What these all have in common is that the load has small or complex airways. These airways create baffles that steam has trouble navigating. Bioreactors fall into this category.

Tests indicate that a standard 20 minute autoclave gravity cycle (that is, one with no vacuum stages) will not effectively sterilize a bioreactor (i.e., raise the entire load to 121ºC and hold it at that temperature for at least 15 minutes). During a standard gravity cycle, most surfaces and areas of the bioreactor reached sterilization temperatures of 121ºC for at least 15 minutes. Unfortunately, the bioreactor vessel itself only reached 121ºC for a few minutes—not long enough to ensure sterilization. The narrow thermowell never got to sterilization temperatures at all.

Bioreactors Need an Autoclave with Vacuum Options

As is the case with most porous loads, adding “vacuum stages” to the sterilization cycle helps enormously. By drawing a partial vacuum in the chamber at the beginning of the cycle, and then “pulsing” this vacuum as steam enters the chamber, the autoclave churns the air and steam in the chamber, forcing steam through the load and into narrow channels and deep containers. This effectively ensures even steam contact throughout the bioreactor.

Given the complexity of a bioreactor and the many opportunities to create cold pockets that lock steam away from surfaces, we recommend several vacuum pulses, in addition to pulsed freesteaming. Using three pre-cycle vacuum pulses virtually guarantees successful sterilization. During his tenure at California State University, Fullerton, Philip Berriman tested various autoclave practices and noted that “Priorclaves are better than most when you use the freesteaming, especially if you use pulsed freesteaming. It does a good job of mixing the air up in there and reliably heating the entire load.”

Consider a Vertical Top-Loading Autoclave

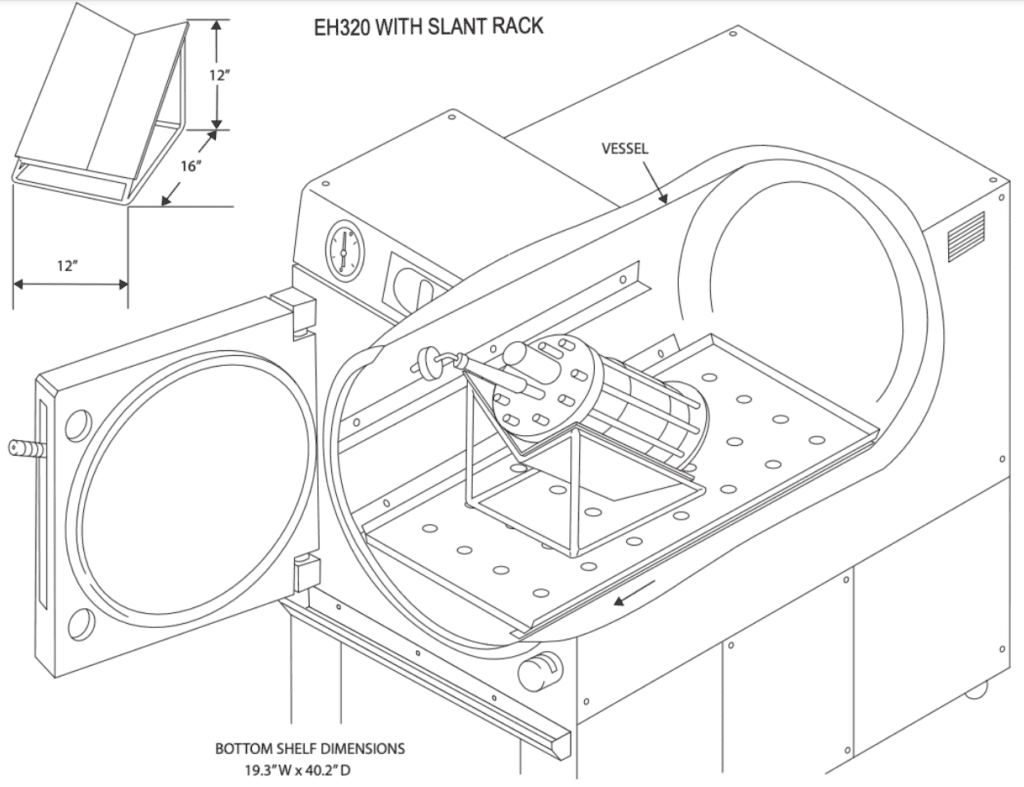

In North America, front-loading horizontal autoclaves are the standard. But it’s usually a struggle to load a bioreactor into a front-loader—even more so if the vessel contains any media. A “slant rack” can help, but often not much:

As Priorclave Managing Director Tony Collins notes: “To accommodate bioreactors in front loaders without laying them down, you would need a tall autoclave chamber that most likely would be as wide as it is tall. In most cases, that’s going to be an expensive autoclave to purchase, take up more space in the lab, and be more expensive to run. Especially when you consider that you’re going to be running it mostly empty, just to accommodate that tall bioreactor.”

Tony urges North American labs to consider an option popular with many of their colleagues overseas: a vertical top-loading autoclave. “These have the advantage of being able to accommodate tall items such as bioreactors with a very small footprint,” Tony explains. “With the optional Loadlite hoist, you can get the most cumbersome bioreactor into the tallest autoclave without strain.”

At Priorclave, our goal is always to match every lab with the autoclave that will best serve their needs. Ready to discuss what you’re trying to accomplish? Contact us to start a conversation.