Autoclaves for Accelerated Aging, Shelf Life, and Medical Devices Testing

Performance, longevity, and shelf life matter when companies are designing and manufacturing products for the marketplace. But how can you reliably and efficiently assess how a product will age and hold up over years of use?

Medical device developers, food and beverage makers, packaging plants, manufacturers, and researchers all rely on accelerated aging tests to approximate the strength, lifespan, performance, and physical integrity of their products or packaging over time. By using controlled heat and humidity, researchers and manufacturers can accelerate and intensify the conditions under which a product or packaging might be stored or used, thus providing important information about aging conditions, aging rate, shelf life, and guidelines for establishing expiration dates. Accelerated aging can also help companies set expectations for the conditions under which their products will perform best, offering users better information about how to optimize product usage. Simulated aging data can increase speed to market by providing important answers about the aging process and how a product conforms to ATSM F1980 standards.

Accelerated Aging, Destructive Testing, Stability Testing, and more

Accelerated Aging tests have different names in different industries. Consumer goods and construction materials are subjected to “accelerated durability studies” (sometimes called “destructive testing”). Canned foods and shelf-stable foods undergo “accelerated shelf life testing.” Pharmaceutical companies put products (both drugs and their packaging) through mandated “stability testing.” Medical equipment manufacturers explore medical device accelerated aging to simulate the shelf life of medical devices and medical device packaging.

Whatever you call your industry’s aging studies, accelerated aging amounts to subjecting samples to elevated temperatures and humidity to simulate real-time aging.

In many cases, an off-the-shelf environmental chamber is sufficient for this kind of accelerated aging test. Even some critical applications can be handled by something only marginally more complex than a home oven. In these situations, provided you can verifiably maintain a steady temperature of 60ºC for weeks on end, then you can reliably simulate years of shelf-life under normal conditions.

But there are some applications that require more than a steady temperature. This is especially the case when testing advanced synthetic materials, electronics, or medical devices or package integrity under ASTM standards (such as ASTM F1980).

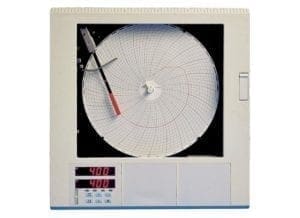

In the real world, these items may be subjected to massive swings in temperature, pressure, and relative humidity. Good accelerated aging testing for these conditions demands equipment with precise and accurate temperature and pressure controls, customizable pressure and temperature ramps, detailed logging, automatic cycle repeat, and a flexible programmable control system.

The Fundamentals of Accelerated Aging Tests

Most material degradation mechanisms are governed by well understood chemical reactions. This is because many chemical reaction rates approximately double with each temperature increase of 10ºC. As such, for monolithic synthetic materials—such as closed-cell foams, plastics, and polymers—it’s easy to reliably double their aging rate. On the other hand, for many natural materials (like paper), a 10º increase can make that item age hundreds of times faster, especially as you begin to vary humidity, UV exposure, and other factors.

Steam-fed industrial sterilizers have been a regular part of industrial accelerated aging and shelf life testing for decades. But today’s autoclave market is dominated by purpose-built jacketed sterilizers. These units are optimized for a specific task—like curing composites or sterilizing instruments to be used during medical procedures. As such, they lack the flexibility, ease of use, and robustness of more traditional “general purpose” laboratory autoclaves.

A general-purpose lab autoclave offers significant energy and cost savings over purpose-built sterilizers. More importantly, they have a much broader operational range with much greater cycle flexibility. For example, every Priorclave self-life testing autoclave can easily run cycles of not just 0 to 120 minutes (standard medical cycles), or 0 to 999 minutes, but 0 to 999 hours—with “Automatic Cycle Repeat,” if needed. With a Priorclave, test items can be subjected to hundreds of identical temperature and pressure ramps without human intervention or “babysitting.” A lab working on materials for military R&D can put a sample of their newest ballistic material in a Priorclave, push a single button, and walk away. Their Priorclave will run for weeks on end, simulating years of exposure to harsh conditions.

Priorclave Accelerated Aging in the Field

Manufacturers and researchers have used Priorclaves to develop new food and medical packaging materials, test the limits of the lead-free solder connections in cell phones, and simulated the weathering endured by spacecraft thermal tiles. For years, the U.S. Army has had a Priorclave at their Aberdeen Proving Ground, where it is used for accelerated aging and destructive testing of ballistic materials.

Today, Priorclave autoclaves are used for accelerated aging in food and beverage, construction, automotive, and even library and archival sciences. Accelerated aging tests cover environmental factors like weather, humidity, and UV exposure to help architects and builders determine which materials will be best suited for new construction projects. Automotive engineers rely on accelerated aging to examine the long-term reliability and durability of engines, batteries, and other components. Archivists use accelerated aging to study the degradation of paper and other archival materials used in conservation efforts. Food and beverage companies use essential accelerated aging data to estimate shelf life and stability of flavor and texture over time. The list of applications across industries goes on and on.

Priorclave for Medical Devices and Pharma

Medical device manufacturers and biomedical research and development labs regularly use Priorclave autoclaves to answer important questions about durability, longevity, shelf life, and proper storage and sterilization protocols.

In 2015, Blue Belt Technologies was working on a new robotics-assisted suite of tools to improve partial and total knee replacement surgery. The system relied on several reusable components that must be sterilized after each procedure, including an electrical sensor encased in metal and plastic and assembled with epoxy. Blue Belt had a variety of concerns about how this device would hold up to repeated uses and sterilization. They wanted to run it through hundreds of sterilization cycles, but off-site accelerated aging testing services were expensive, and conventional autoclaves needed to be manually operated and monitored. Under these conditions, even a single testing cycle took months. With our help, Blue Belt increased prototype testing throughput by 500%, doing months of testing in mere days—twice the work in half the time.

Companies also use Priorclaves to approximate real-time aging factors, such as ambient temperature and relative humidity, to help determine the integrity of sterile barriers for packaging. In the UK, Priorclave has been outfitting contact lens manufactures with both R&D and production autoclaves for more than 20 years. Globally, contact lenses are a $9.6 billion industry that’s expected to grow to $15.2 billion over the next decade—and disposable silicone hydrogel lenses are an enormous part of that growth. Robust blister packs are essential for maintaining sterile barrier integrity that allows for post-packaging lens sterilization, and an acceptable shelf life for packaged lenses. Early on, Priorclaves helped manufacturers develop both the production and packaging process needed to make silicone hydrogel lenses a viable product.